Cleaning of water and glycol installations

Cleaning of water and glycol installations

Safe chemical cleaning technology

Cleaning of equipment and pipelines from corrosion products, water and glycol precipitates based on many years of experience and nanotechnology

NAGARE – is a modern, effective and at the same time completely safe technology for the chemical cleaning of installations, heat exchangers from corrosion products and precipitated deposits from water and glycol.

ADVANTAGES OF MBA S.A. TECHNOLOGY

- Tested by UDT, GIG, PZH

- Cleaning without hydrochloric acid!!!!!

- Safe for equipment, people and the environment

- Possibility of cleaning the bases of disassembly of the equipment.

- Inert to fittings and accessories installed in the plant

- Cleaning possible during the season/operation

- Low cleaning costs

- Experience - 25 years on the market.

INDUSTRY

Cleaning, etching of stationary installations including heat exchangers, condensers, coolers, compressors and power equipment in industrial facilities

CENTRAL HEATING BOILERS

- Regeneration and decalcification of all types of central heating boilers, including steam boilers

RESIDENTIAL AND SOCIAL BUILDINGS

- Digestion and removal of scale deposits in all central heating and hot water installations of residential buildings, multi-family buildings, hotels, hospitals, schools, etc.

Health and safety for people

- No toxicity: They do not contain corrosive acids or dangerous bases. Safe NAGARE preparations are free from toxic chemicals, which minimizes the health risk to people operating installations and building users.

- Protection against irritations: NAGARE preparations are hypoallergenic and do not cause skin or respiratory tract irritations.

- Removal of bacteria from installations - legionella, e.coli - NAGARE preparations remove 100% of accumulated bacteria that are dangerous to humans from installations.

- Work safety: Using non-toxic NAGARE agents reduces the risk of accidents and poisoning during work, which is crucial in maintaining safe working conditions. Health and Safety regulations must be followed.

Machine durability and efficiency

- Removal of scale and deposits: Effective cleaning with NAGARE technology removes boiler scale, deposits

and corrosion, which increases the thermal efficiency of devices and installations. - Increased service life: Regular cleaning with NAGARE products prevents damage

and premature wear of devices, which leads to their longer service life and reduced costs of purchasing new devices. - Optimal operation: Successive cleaning ensures optimal operating conditions of systems, which translates into

their energy efficiency and reduced operating costs.

ECONOMIC BENEFITS

- Reduced repair costs: Regular and effective cleaning reduces the risk of breakdowns and the need for expensive repairs.

- Energy savings: Clean systems operate more efficiently, leading to lower energy consumption and lower electricity and gas bills.

- Extended service intervals: Good system cleanliness allows for longer service intervals, which translates into financial savings.

TECHNOLOGICAL BENEFITS

-

Compliance with modern standards: Modern cleaning agents comply with current standards

and technical standards, which ensures their effectiveness and safety. -

Ease of use: NAGARE products are easy to use and require minimal training, which makes them easier to use

in practice. Possibility of cleaning during system operation and the heating season.Using NAGARE technology and agents for cleaning installations, heat exchangers, coolers, condensers, cooling systems, domestic hot water and central heating brings many benefits. It ensures people's health and safety, improves the durability and efficiency of devices, protects the environment and generates real financial savings.

Hydrochloric acid

Is a corrosive liquid, emits poisonous and caustic vapours and has a corrosive effect. Under normal conditions it is a colourless or slightly yellow liquid, fuming in air. A strong acid that is very chemically active. Hydrochloric acid reacts with most metals giving off hydrogen, creating an explosion hazard and a danger to the environment and health!!!

Hydrochloric acid digestion

Commercial hydrochloric acid HCl (d = 1.18 g/cm3, approx. 36% by weight) is a yellow-coloured liquid. Its vapours mixed with moisture form a "mist". These vapours have a harmful effect on mucous membranes and a strong corrosive effect on apparatus and equipment. Hydrochloric acid is more aggressive than sulphuric acid, dissolves corrosion products more evenly and etches the substrate more quickly. Subjects etched in hydrochloric acid show better surface condition BUT are hydrogenated. Ferric chlorides can be easily rinsed off the surface BUT inadequate rinsing can result in corrosion centres.

Inhibitors

In the environment, substances called inhibitors can significantly reduce hydrogen entry into a metal. Hydrogen entry inhibitors are multi-component mixtures containing oxygen, nitrogen and sulphur. Corrosion inhibitors are usually polar organic compounds that are strongly absorbed on the metal surface. Most commonly, corrosion inhibitors reduce the rate of electrochemical corrosion occurring and, in the case of corrosion with hydrogen depolarisation, also reduce the rate of hydrogen si release. Not all corrosion inhibitors reduce hydrogen ingress. In some environments, there may be enhanced hydrogen uptake in the presence of inhibitors.

The presence of hydrogen in metals and alloys adversely affects their physical, mechanical and electrochemical properties, manifested, inter alia, in reduced mechanical strength and increased brittleness. Independently of these phenomena, hydrogen intensifies the course of corrosion processes in steels and alloys. Under the influence of hydrogen, steel and alloys are damaged in different ways.

When cleaning with hydrochloric acid without inhibitors in the correct dosage for the metal in question (analysis of the composition of the device to be cleaned), the device is damaged after max. 3 cleanings. Permanent and irreparable pitting occurs.

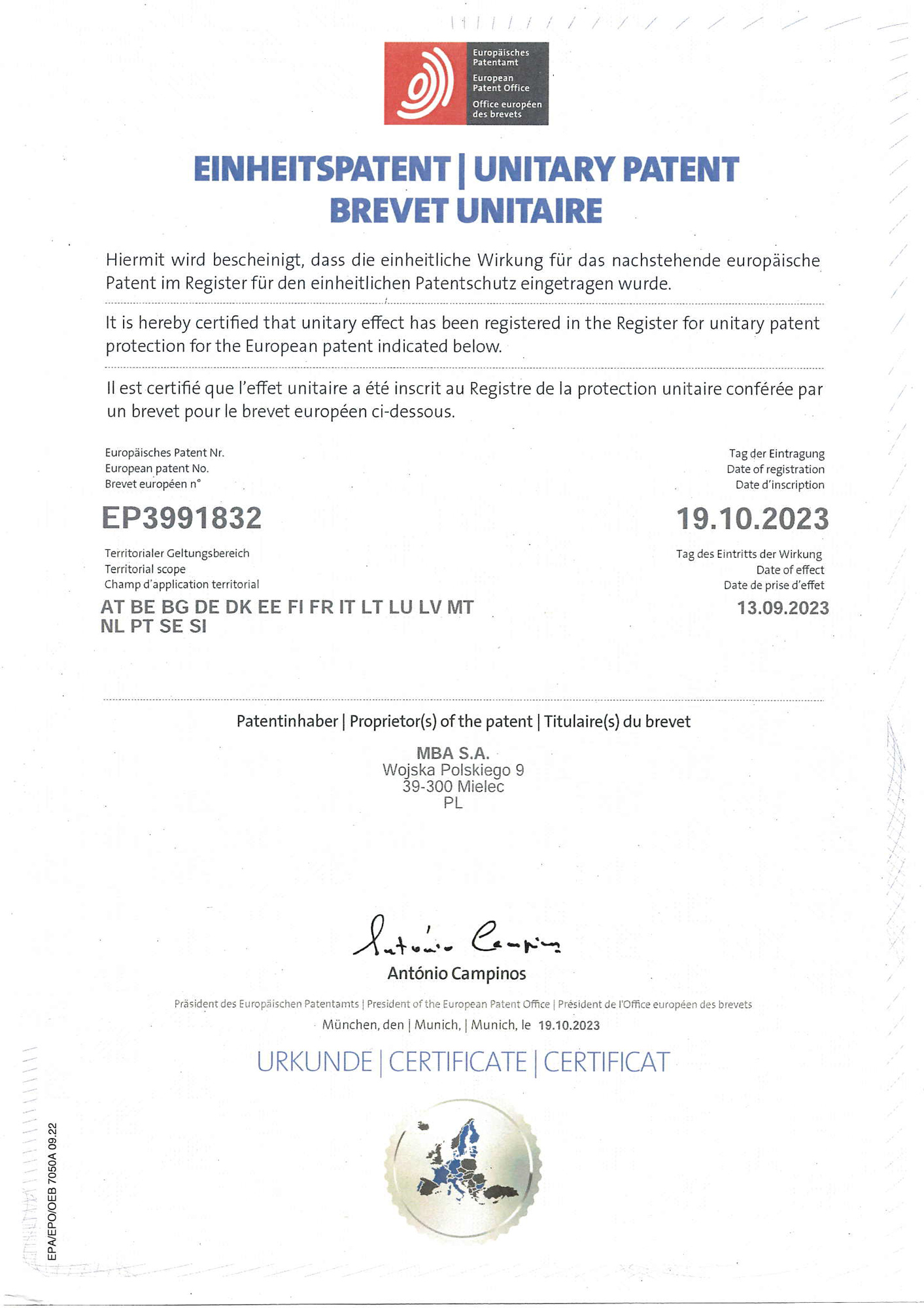

MBA S.A.

Research & Recommendations

MBA S.A.

Make your first step the right one